As an industry expert in handheld laser welding machines, Baishuo Laser is delighted to provide you with a comprehensive introduction to the topic.

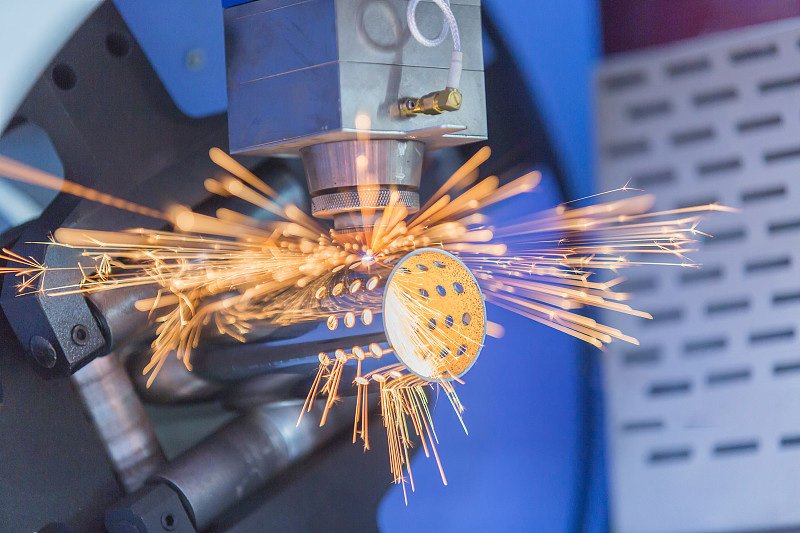

Handheld laser welding machines have gained popularity in recent years due to their versatility and efficiency in various applications. These machines are widely used in industries such as sheet metal fabrication, cabinets, kitchenware, advertising, and more.

The Role of Auxiliary Gas:

Auxiliary gas is crucial for shielding during the welding process. Inert gases like argon, helium, and nitrogen are commonly used as they are colorless, odorless, and chemically inactive. By spraying inert gas onto the workpiece’s surface, oxidation of the weld seam is prevented, improving aesthetics and reducing spatter.

Types of Auxiliary Gas:

Argon: Cost-effective and commonly used for its excellent protection of welds on various metals.

Nitrogen: Affordable but limited in welding certain stainless steel types due to potential porosity issues.

Helium: More expensive but offers superior protection and allows unobstructed laser access to the workpiece.

Using Auxiliary Gas:

Smoothly move the gas tank during use.

Set the auxiliary gas before turning on the laser welding machine.

Open the cylinder valve slowly, standing on the side of the bottle mouth.

Choose the appropriate blowing method, such as side-blowing from the side shaft.

Store the gas away from fire sources and avoid high temperatures or direct sunlight.

Choosing and using the auxiliary gas for a handheld laser welding machine is crucial for achieving optimal welding results. Here are some important considerations and steps to follow:

Gas Selection: The most commonly used auxiliary gases for laser welding are argon, helium, and nitrogen. The choice of gas depends on the material being welded and the desired welding characteristics. For example, argon is suitable for welding stainless steel, while nitrogen is preferred for aluminum.

Gas Purity: Ensure the purity of the selected gas. High-purity gases are essential to avoid impurities that can negatively impact the welding process and result in poor weld quality.

Gas Flow Rate: The appropriate gas flow rate is essential for shielding the welding area and preventing oxidation during the process. Follow the manufacturer’s guidelines or conduct test welds to determine the optimal gas flow rate for your specific application.

Nozzle Design: Select the appropriate nozzle design for the handheld welding machine. The nozzle should provide efficient gas delivery to the weld area and help maintain a stable welding process.

Gas Pressure: Set the gas pressure correctly to maintain a consistent gas flow. Proper gas pressure ensures effective shielding and prevents contaminants from entering the weld zone.

Gas Delivery System: Ensure that the gas delivery system is well-maintained and free from leaks. Regularly inspect and replace gas hoses and fittings to prevent interruptions in gas supply during welding.

Welding Environment: Weld in a controlled environment with minimal air movement or drafts. This helps maintain the effectiveness of the gas shielding and reduces the risk of contamination.

Monitoring and Adjustment: Continuously monitor the gas flow and adjust as needed during the welding process to maintain optimal conditions.

Training and Experience: Properly train operators on gas selection and usage for the specific handheld laser welding machine. Experienced operators can make critical adjustments to ensure high-quality welds.

Safety Measures: Always follow safety guidelines and wear appropriate personal protective equipment when handling and using auxiliary gases.

Advantages of Handheld Laser Welding Machines:

Versatility: Suitable for welding various materials like aluminum, iron, stainless steel, and copper sheets.

High Precision: Utilizes high-intensity laser beams for accurate and clean cuts.

Efficiency: Fast cutting speeds increase production throughput.

Non-Contact Cutting: Minimizes deformation and surface damage to the workpiece.

Environmentally Friendly: Reduces waste production and consumes relatively low power.

In comparison to CNC, Plasma Laser, Waterjet, and Flame cutters, handheld laser welding machines offer superior precision, minimal heat-affected zones, faster cutting speeds, and the ability to work with various materials. They are indispensable tools for modern industrial production, providing high-quality cutting solutions for metal fabrication, automotive, aerospace, electronics, and other industries.

At Baishuo Laser, we offer a wide range of handheld laser welding machines and professional support to help you choose the right equipment for your specific needs. Contact us to learn more about our products and services.