As an industry expert in laser cutting machines, Baoshuo laser pleased to provide you with a comprehensive and detailed introduction to the topic: How Does A Fiber Laser Cutting Machine Work, And How To Choose The Right One?

How Does A Fiber Laser Cutting Machine Work?

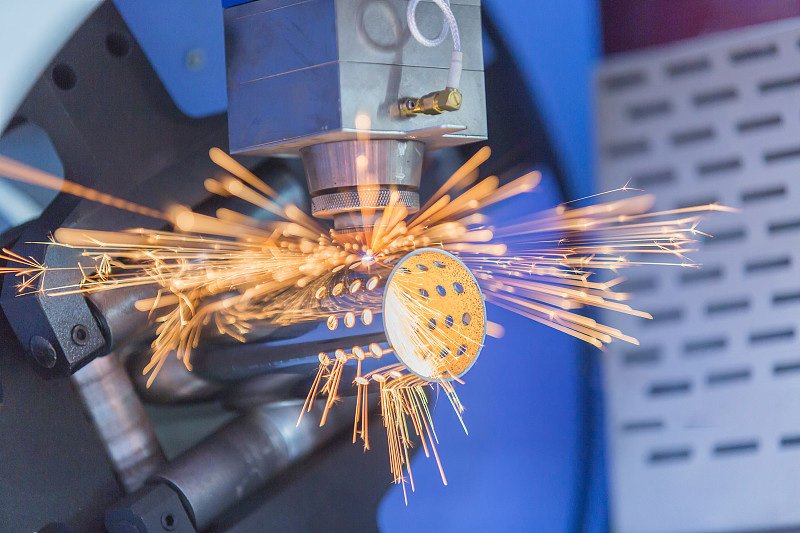

A fiber laser cutting machine utilizes advanced laser technology to achieve high precision and efficiency in material cutting. The process involves focusing a powerful laser beam onto the workpiece, causing the material to melt, burn, or vaporize, resulting in clean and accurate cuts.

Generation of Laser Beam: The laser beam is generated through a fiber laser resonator, where rare-earth elements such as yttrium, terbium, or neodymium are excited by diode pumping.

Beam Delivery: The laser beam is transmitted through fiber optic cables to the cutting head, where it is focused into a small and intense spot.

Material Cutting: The focused laser beam is irradiated onto the surface of the workpiece, causing the material along the cutting path to melt or evaporate. Simultaneously, high-pressure inert gas (typically oxygen or nitrogen) is jetted onto the cutting area to blow away the melted material, resulting in a clean cut.

CNC Control: The entire cutting process is controlled by Computer Numerical Control (CNC) technology, precisely coordinating the movement of the laser cutting head and the workpiece to achieve the desired shape and size.

How To Choose The Right Fiber Laser Cutting Machine?

Power Output: Consider the power output of the fiber laser cutting machine, as it determines the cutting capability and speed. Higher power machines are suitable for thicker and harder materials.

Cutting Area: Determine the required cutting area size. Choose a cutting bed that can accommodate your largest workpieces.

Material Compatibility: Confirm that the machine can cut the materials you work with, such as stainless steel, carbon steel, aluminum, brass, copper, or other special alloys.

Cutting Speed and Precision: Look for a machine with high cutting speed and precision to improve production efficiency and achieve fine cutting results.

Automation and Software: Consider the level of automation and user-friendly software features of the machine to simplify operation and enhance efficiency.

Maintenance and Support: Choose a machine that is easy to maintain and has reliable technical support to minimize downtime and ensure smooth operation.

Safety Features: Ensure the machine has appropriate safety measures to protect operators and prevent accidents during cutting.

Price and Return on Investment: Compare the cost of the machine with its features and capabilities to ensure your investment yields a good return.

Brand Reputation: Select a reputable and reliable manufacturer with a proven track record of producing high-quality fiber laser cutting machines.

By carefully assessing your specific needs and considering these factors, you can choose the fiber laser cutting machine that best suits your application, achieving optimal cutting results in your industry. Whether you are involved in metal processing, automotive manufacturing, aerospace, electronics production, or other fields, laser cutting machines will provide you with top-notch cutting solutions, helping you enhance production efficiency and product quality. If you want to learn more about fiber laser cutting machines, please feel free to contact us.